NEW Cygnus Underwater

Diver-Held Thickness Gauge

- Designed for divers needing to take reliable thickness measurements of underwater structures, the Cygnus Underwater diver-held gauge provides quick and accurate metal thickness measurements through coatings or even heavy corrosion.

- Available for PRE-ORDER NOW

Specifically designed for divers undertaking ultrasonic thickness measurement (UTM) of underwater structures. The Cygnus Underwater diver held gauge has been built to withstand harsh subsea environments while providing quick and accurate metal thickness measurements through coatings or heavy corrosion. This diver-held thickness gauge is simple to operate using 3 function keys, an intuitive menu and a large LCD display – highly visible, even in low-visibility waters.

Key Features:

- 3 measuring modes for levels of corrosion, various materials and through-coat measurements

- Depth sensor – live depth display providing the diver with an accurate depth indicator

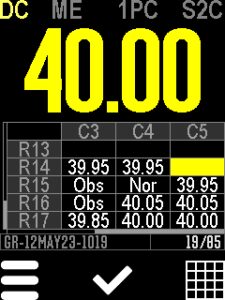

- Live A-Scans aid visual measurement verification

- Extremely Simple-to-Use with 3 function keys and up to 4 screens

- Comprehensive data-logging: linear and grid

- Deep Coat function ignores thick coatings

- RTC (Real Time Clock) for tagging date/time on measurement points

- Auto-set Gain to optimise the probe’s gain settings for optimal performance

- Multiple Echo Mode to verify accurate through-coat measurements as specified by Class Societies

- Measurement Stability Indicator (MSI) verifies stable and therefore reliable measurements

- Available in STD, PLUS and PRO variants with upgradeable options, e.g. Topside Repeating and Data Logging (download the Cygnus Underwater Variants Comparison Guide).

Whether you need a reliable Underwater Thickness Meter or an efficient Underwater Thickness Gauge, our Cygnus instruments offer top-notch performance and accuracy for your underwater measurement needs.

Other products and services we offer:

| Measuring Modes | Single Echo with Twin Crystal Probes Echo-Echo with Twin Crystal Probes Multiple Echo with Singly Crystal Probes |

| Materials | Sound velocity from 2000 m/s to 9000 m/s [0.0787 in/us to 0.3543 in/us] |

| Accuracy | ±0.1 mm (±0.004”) or 0.1% of thickness measurement whichever is the greatest |

| Resolution | 0.1 mm, 0.05 mm or 0.01 mm depending on probe type |

| Probe Options | Single crystal and twin crystal probes |

| Measurement Range in Steel | 1 mm to 250 mm (0.040 in. – 10 in.) depending on selected probe and configuration, material and temperature |

| Connector | SubConn MC |

| Power Supply | Ni-MH battery pack 1.8 Ah (min) |

| Power Rating | 1.5W |

| Probe Sockets | Lemo |

| Battery Life | 8 hours minimum continuous measurement |

| Display | 2.4” VGA, sunlight readable colour display |

| Size | 80 x 305 x 65 mm (W x L x D) |

| Weight | 1 kg with battery |

| Operating Temp. | -10°C to +50°C (14°F to 122°F) |

| Storage Temp. | -20°C to +60°C (-4°F to 140°F) |

| Data Logging | 5,000 measurements and A-scans per record |

| Computer Software | CygLink allows remote logging and viewing of A-scan graphs. Survey and report generation to PDF file. Graphic analysis of data and statistical calculations. Data output via RS-485 serial connection to transfer data to a Windows® computer with CygLink. |

| Depth Senor | Range 0 – 300 m (30Bar) |

| Environmental Protection | Depth rated for 300 m continuous immersion in sea water MIL STD 810G Method 501.6 (High temp. +55°C) MIL STD 810G Method 502.6 (Low temp. -20°C) |

| Shock & Impact | MIL STD 810G Method 514.7 (Vibration) MIL STD 810G Method 516.7 (Shock 20g) MIL STD 810G Method 516.7 (Transit Drop 1.22m) |

| Standards | Designed for BS EN 15317 RoHS Compliant |

| Warranty | 3 years on gauge and 6 months on probe |

Cygnus Underwater Variants Comparison Guide

Cygnus Subsea Gauge Family Brochure

View List of Spares & Accessories

Reviews

There are no reviews yet.