Celebrating 40 Years of

Reliable Ultrasonic Measurement

Reliable Ultrasonic Measurement

40 years ago Cygnus were the original pioneers, developing digital multiple echo technology to obtain accurate thickness measurements through coatings and corrosion.

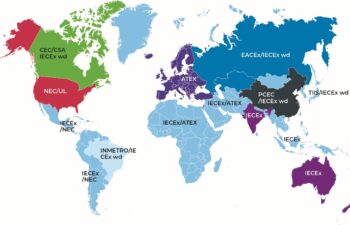

Cygnus manufacture and supply ultrasonic thickness gauges which are employed in almost every industrial application around the world.

With successful diversification, Cygnus now carries three ultrasonic product lines – thickness gauges, a hatch cover/water-tight door leak detector and a flooded member detector (FMD) system.

About CygnusFeatured Industries

Featured Products

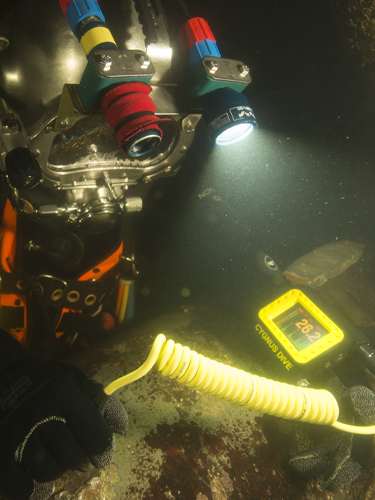

NEW Cygnus Underwater

Designed for divers needing to take reliable thickness measurements of underwater structures, the Cygnus Underwater d...

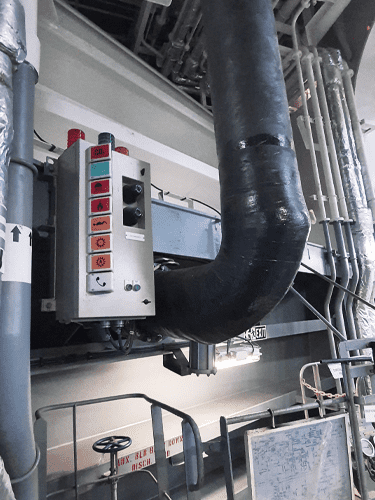

More InfoCygnus 1 Ex

Designed for taking reliable thickness measurements in Zone 0 Explosive Atmospheres and boasting advanced data loggin...

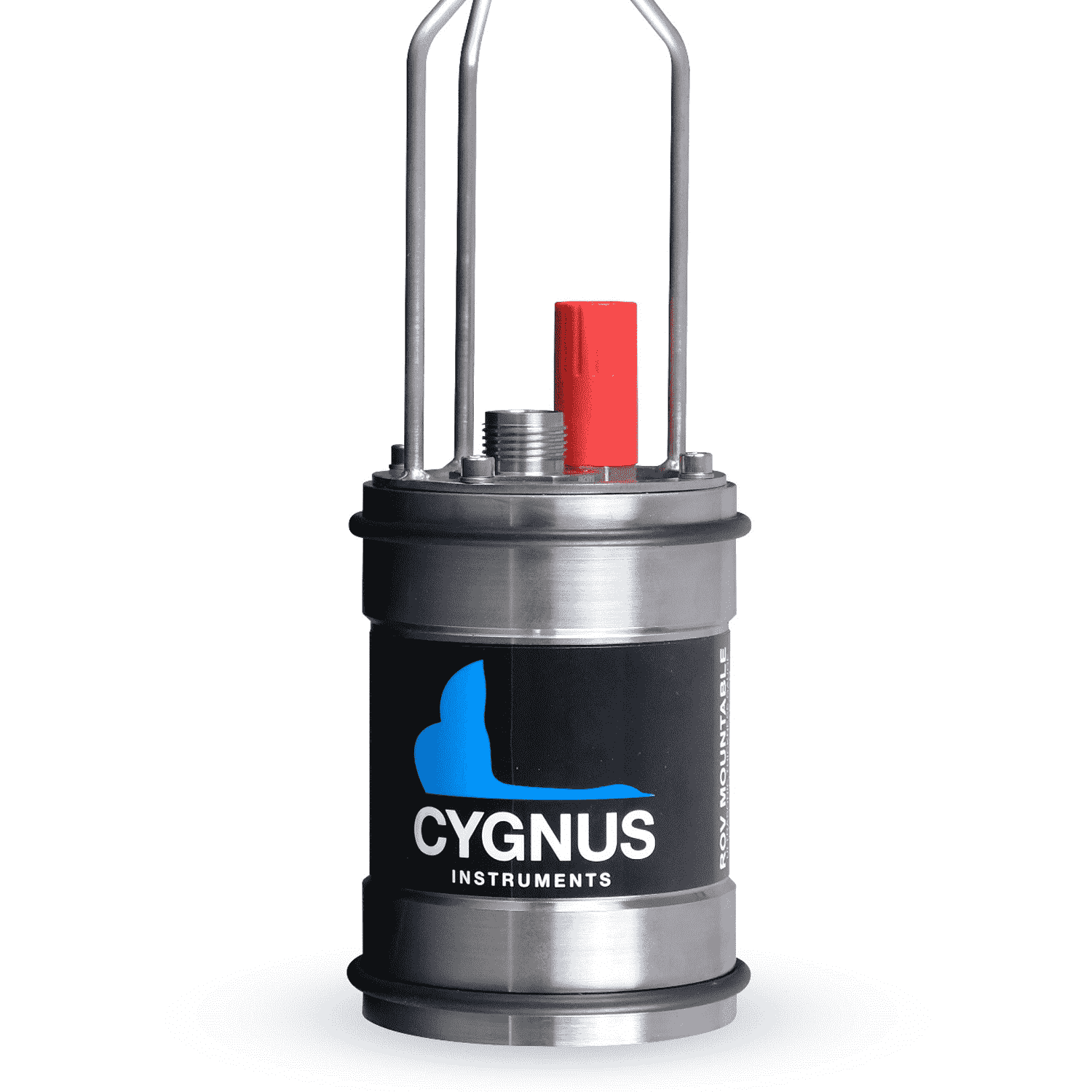

More InfoCygnus ROV UTM

This dedicated ROV mountable thickness gauge is depth rated to 3,000m, has live A-scan, a piezo-composite probe and s...

More InfoCygnus 6+ PRO

Boasting a full range of useful features for professional users, including: A-scan; B-scan; comprehensive data loggin...

More InfoCygnus 4+ General Purpose

A versatile thickness gauge used for a wide range of applications, the Cygnus 4+ offers: live A-scan display; sequent...

More InfoHigh Temperature Probe

Twin element ultrasonic probe designed for high-temperature, in-service thickness measurements and corrosion surveys ...

More InfoWhat our customers say

Results

Featured Posts

See you at the show?

Cygnus Instruments have a busy few weeks ahead and will be showcasing a selection of our ultrasonic testing equipment at the following events: 20th WCNDT in Korea; Posidonia in Greece; Seawork in the UK; NDT in Canada. Find out more about the events Cygnus Instrument...

Read More