High Temperature Probe

Twin Element Ultrasonic Probe designed for high-temperature, in-service thickness measurements and corrosion surveys across oil & gas, refining, energy and process sectors.

- No cooling period required – reducing inspection time and facilitating effective measurement

- For use on hot surfaces up to 300 degrees C

- Measures remaining wall thickness from 1.5mm to 250 mm – depending on temperature and material.

At Cygnus Instruments, we pride ourselves on our pioneering spirit and four decades of innovation in the development of digital Multiple Echo technology. Our expertise has led us to craft an extensive range of ultrasonic thickness gauges, specifically designed to meet the rigorous demands of industries requiring high-temperature probes.

With a global presence and a team of highly trained professionals, we are dedicated to delivering exceptional performance in even the most challenging conditions. Should you require assistance or wish to explore our high-temperature solutions, please don’t hesitate to contact us on +44 (0) 1305 265 533. We’re here to support your needs with precision and reliability.

The Best Place to Purchase High-Temperature Probes

High-temperature probes are indispensable in various sectors, providing accuracy and safety in environments of extreme heat. But what are they precisely, and how do they operate under such intense conditions? In this piece, we explore the intricacies of high-temperature probes, shedding light on their design and functionality.

Discover how these durable devices are crafted to withstand blistering temperatures, all the while maintaining precise measurements. We’ll also take a closer look at the innovative high-temperature probes supplied by Cygnus Instruments, showcasing the advanced technology that distinguishes us. Delve into the science behind these exceptional tools and their crucial role in ensuring the integrity of vital operations.

What is a High-Temperature Probe?

A high-temperature probe is a bespoke instrument crafted to endure extreme thermal conditions, ensuring precise measurements are maintained. These probes are built with an emphasis on durability and accuracy, proving indispensable across a plethora of sectors. Notably, ultrasonic probes, designed for gauging thickness in high-heat environments, stand out for their application-specific utility.

Their prowess in navigating demanding test scenarios guarantees the collection of trustworthy data, even under severe conditions. Utilised extensively in industrial domains, aerospace, and any sphere where temperature significantly impacts operations, a robust high-temperature probe is crucial.

Its resilience against harsh environments, coupled with its capacity to deliver precise readings, renders it an essential asset for professionals aiming for reliable and consistent outcomes in their testing endeavours.

How Does it Work?

Our high-temperature probes, crafted for unparalleled precision, stand as indispensable instruments across a myriad of testing scenarios. These sophisticated devices harness the power of ultrasonic technology, a non-intrusive technique celebrated for its accuracy and adaptability. During operation, our probes dispatch high-frequency sound waves into the subject material.

These waves permeate the material and are reflected back to the probe’s sensor. By gauging the duration for the waves’ return journey, our probes deduce the material’s thickness with remarkable accuracy. This method proves especially efficacious for appraising materials subjected to elevated temperatures, guaranteeing dependability under strenuous conditions.

With Cygnus Instruments’ high-temperature probes at your disposal, you’re assured of precise outcomes for your testing requisites, even when operating in high-temperature environments.

Introducing the High Temperature Ex Probe

At Cygnus Instruments, our high-temperature in-service probe is fully compatible with our ultrasonic thickness gauges. Discover the Cygnus High-Temperature Ex Probe below.

Basic Information and Specifications

Our High-Temperature Ex probe stands as the quintessential partner for the Cygnus 1 Ex ultrasonic thickness gauge, masterfully tailored for the rigours of high-temperature settings. This innovative probe empowers you to take uninterrupted measurements on heated surfaces, sidestepping the need for any cooling interludes. Such an approach not only trims down inspection durations but also bolsters the precision of your assessments.

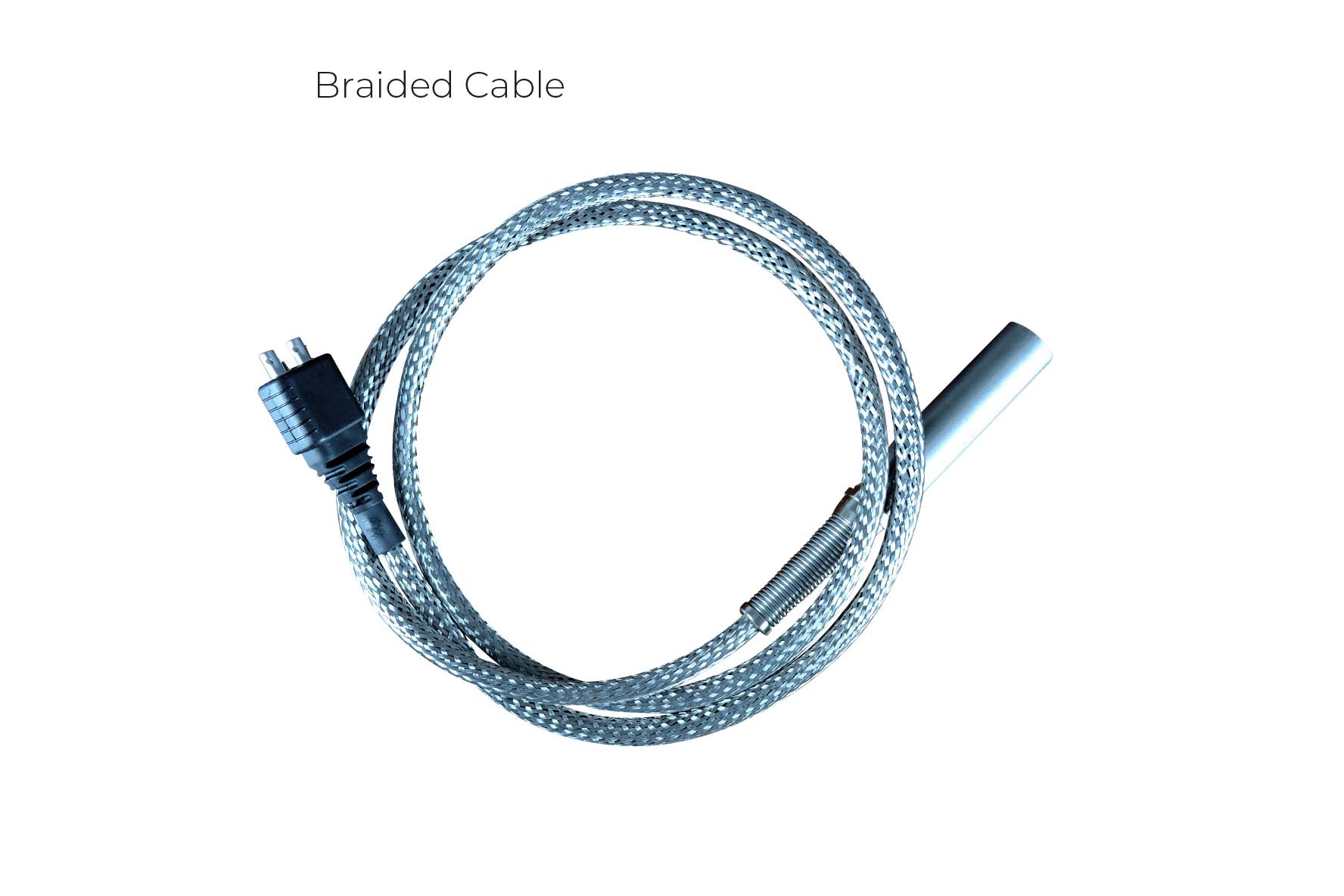

Constructed with resilience in mind, the probe integrates seamlessly with a specialised probe cable, encased in a glass-fibre outer sheath for enhanced safeguarding. It’s worth noting that both the probe and its accompanying cable are available as separate purchases, presenting a cost-efficient pathway for replacements.

In the realm of high-temperature examinations, our probe is engineered to seamlessly align with your requirements, thereby becoming an indispensable component of your toolkit.

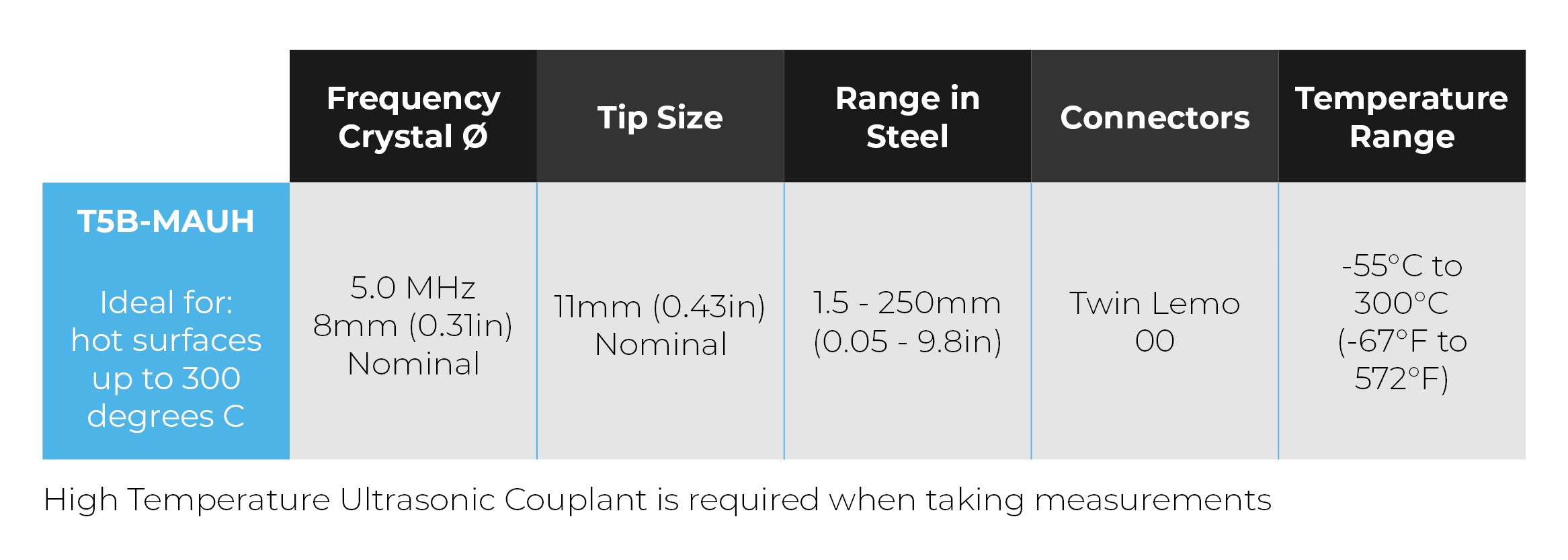

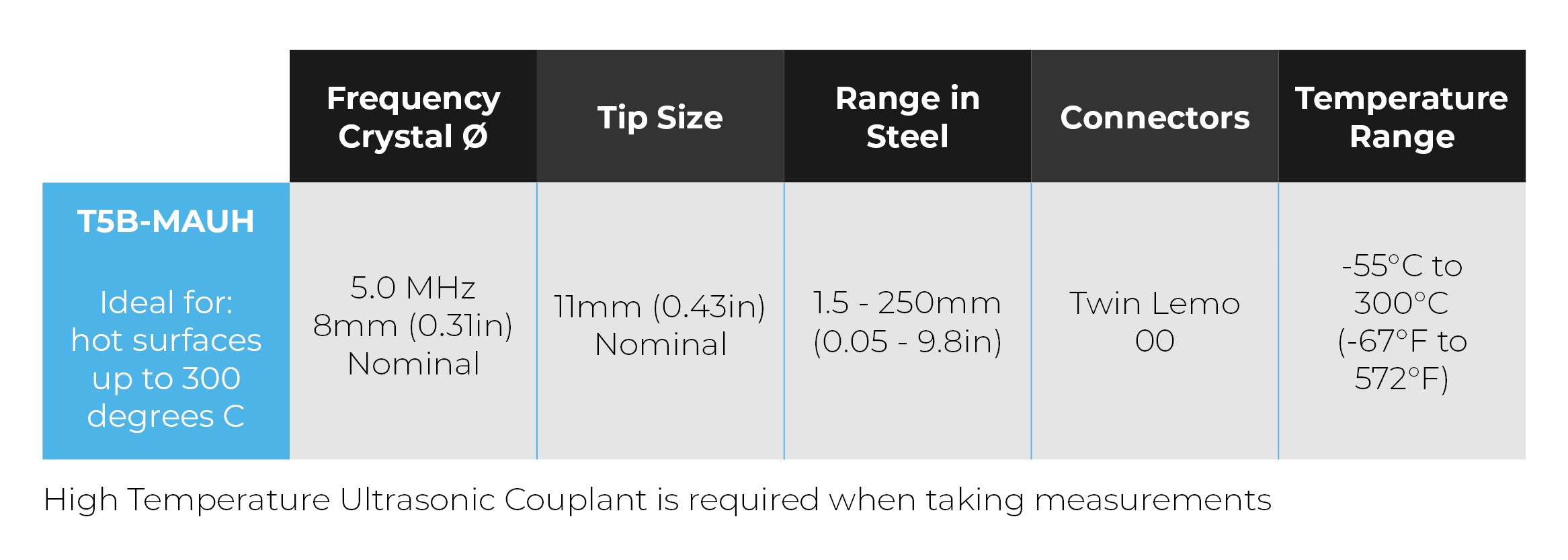

Delving into the specifics, our high-calibre T5BH-Ex temperature probe is adept at navigating extreme environments. Its sturdy constitution makes it the go-to tool for gauging temperatures on torrid surfaces, effortlessly accommodating up to 300 degrees Celsius.

Key attributes include a 5.0 MHz frequency crystal, a nominal tip size of 12 mm, and a measurement range in steel spanning from 2.5 to 50 mm, coupled with Twin Microdot 10-32 connectors.

Bid farewell to the hurdles posed by temperature in your testing endeavours, as our T5BH-Ex probe shines in handling surface temperatures between 50°C and 300°C, ensuring your high-temperature in-service needs are met with unmatched efficacy.

Suitable Applications

Our high-temperature probes are designed to excel in a myriad of industries and testing scenarios, especially where extreme heat is a prevalent challenge. These robust instruments are tailored to withstand the rigours of high-temperature environments, ensuring precision and reliability in every measurement.

Applications of our high-temperature probes include, but are not limited to:

- Furnace and Boiler Inspections: Essential for maintaining the safety and efficiency of heating systems, our probes can withstand the intense environments of furnaces and boilers, providing accurate thickness measurements and detecting potential issues before they escalate.

- Heat Exchanger Assessments: In power plants and chemical facilities, the integrity of heat exchangers is crucial. Our probes facilitate thorough inspections, ensuring these critical components operate safely and effectively under high temperatures.

- Aerospace Material Testing: The aerospace industry demands stringent quality checks for materials subjected to extreme temperatures during flight. Our high-temperature probes offer non-destructive testing solutions, aiding in the evaluation of structural integrity and performance under challenging conditions.

In summary, whether you’re tasked with monitoring heat-related processes or assessing the structural integrity of components exposed to high temperatures, our high-temperature probes stand as your reliable partners, delivering accurate and dependable results across a spectrum of demanding applications.

Why Come to Us for Ultrasonic Thickness Testers

Originating from a strong foundation in Non-Destructive Testing (NDT) for maritime applications, Cygnus Instruments has evolved over 40 years into a leading figure in the realm of ultrasonic testing (UT) equipment, serving an array of industries across the globe.

Our roots in crafting durable, user-friendly devices for ship surveyors and divers have profoundly influenced our product range, which is celebrated for its robustness, reliability, and simplicity.

At the heart of our innovation is the pioneering “Multiple Echo” UT technique, now a standard among major Classification Societies, reflecting our commitment to advancing inspection technology. This dedication to innovation, coupled with valuable customer insights and rigorous R&D, enables us to offer a diverse portfolio of UT solutions.

Our equipment is adept for challenging scenarios, including hazardous areas, ship hull and underwater inspections, asset integrity management, and specialised applications like hatch cover tightness and flooded member detection.

Cygnus Instruments is not only ISO-9001 certified but also boasts intrinsically safe certifications from EX Veritas and CSA, underscoring our commitment to quality and safety. For ultrasonic inspection needs that demand precision, durability, and ease of use, we are your trusted partner.

Contact Us

For enquiries about our high-temperature probes or any other specialised needs, we’re here to assist. Reach out to us directly on +44 (0) 1305 265 533 or drop us an email at sales@cygnus-instruments.com. We understand the critical nature of your requirements, and our team is on standby to provide you with the tailored advice and solutions you seek.

Alternatively, you can use our contact form for a swift response. Your challenges are unique, and so are our solutions. Let’s explore how our high-temperature probe offerings can enhance your operational efficiency and accuracy.

Reviews

There are no reviews yet.