High Temperature Ex Probe

Twin Element Ultrasonic Probe designed for high-temperature, in-service, wall thickness and corrosion surveys across oil and gas, refining, energy and process sectors. Great wear resistance allows for use on hot surfaces up to 300°C. Measures remaining wall thickness from 2.5mm to 50mm - depending on temperature and material.

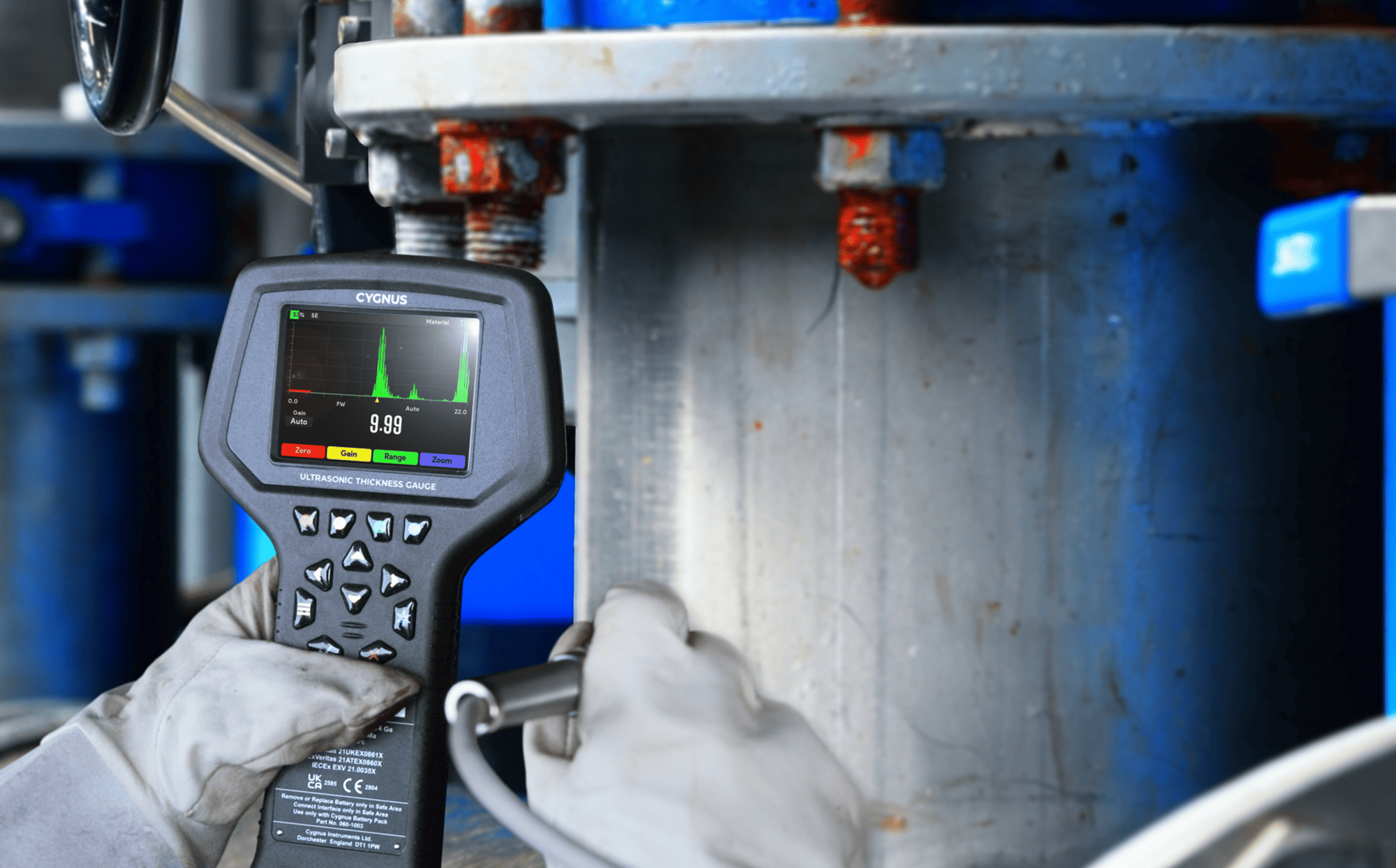

- For use with Cygnus 1 Ex ultrasonic thickness gauge

- AVAILABLE TO ORDER

Engineered to be used with the Cygnus 1 Ex ultrasonic thickness gauge, the High-Temperature Ex Probe can measure hot surfaces continuously without cooling period, reducing inspection time and facilitating more effective measurement!

The probe is designed for use with a special probe cable wrapped in a glass-fibre outer braid to protect the cable.

The probe and probe cable are sold separately, enabling lower replacement costs.

| Frequency Crystal Ø | 5.0 MHz 8 mm (0.31 in) Nominal |

| Tip Size | 12 mm (0.47 in) Nominal |

| Range in Steel | 2.5 – 50 mm (0.1 – 1.97 in) |

| Connectors | Twin Microdot 10-32 |

| Surface Temperature | 50°C to 300°C (122°F to 572°F) |

T5BH-Ex: Ideal for hot surfaces up to 300 degrees C

| Frequency Crystal Ø | 5.0 MHz 8 mm (0.31 in) Nominal |

| Tip Size | 12 mm (0.47 in) Nominal |

| Range in Steel | 2.5 – 50 mm (0.1 – 1.97 in) |

| Connectors | Twin Microdot 10-32 |

| Surface Temperature | 50°C to 300°C (122°F to 572°F) |

Reviews

There are no reviews yet.